Inventory : Inventory Workflows: 3-Step Receiving

Purpose

The purpose of this documentation is to outline the process of implementing 3-Step Receiving in Odoo Version 13. In 3-Step Receiving, products are first received to an internal Input location. Then, they are moved to an internal Quality Control, and finally are manually transferred to an internal Stock location.

Process

To get started, navigate to the Inventory application.

Once there, go to CONFIGURATION > SETTINGS.

Scroll down to the Warehouse section and check Multi-Step Routes. Then, click SAVE.

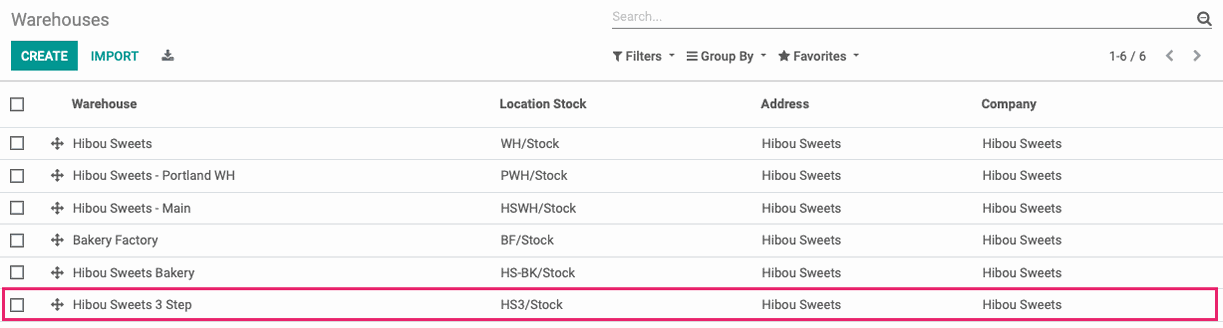

Next, go to CONFIGURATION > warehouses.

From the list, select the Warehouse you wish to configure with 3-Step Receiving.

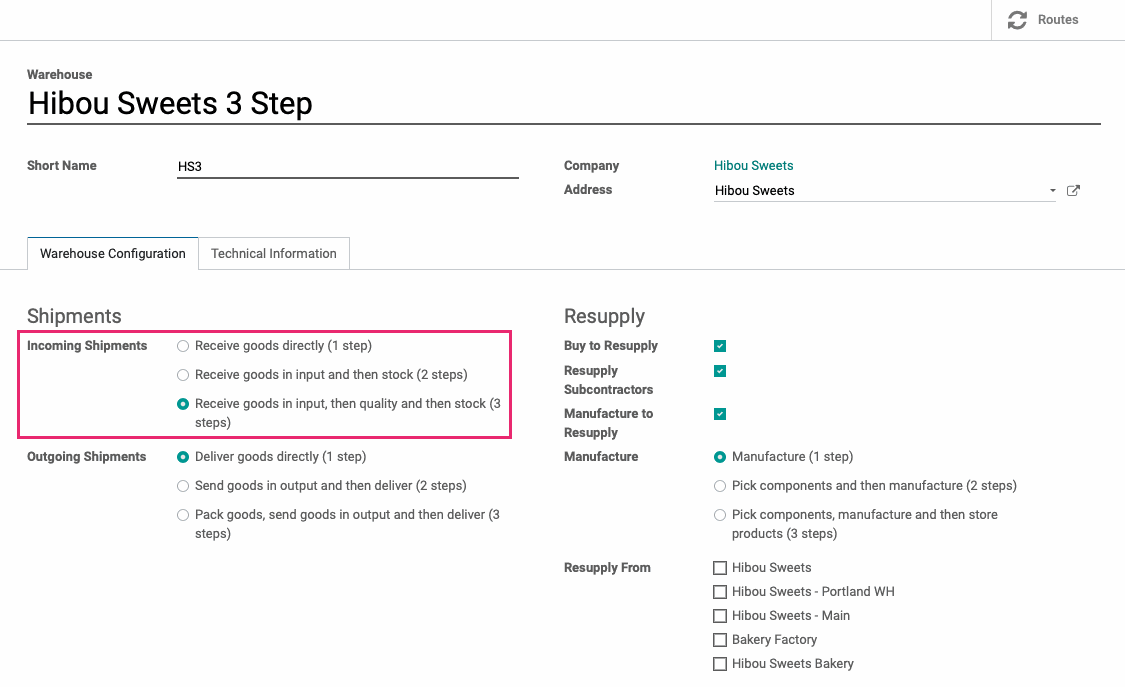

On the Warehouse template, click edit. Under Shipments > Incoming Shipments, select "Receive goods in input, then quality and then stock (3 steps)".

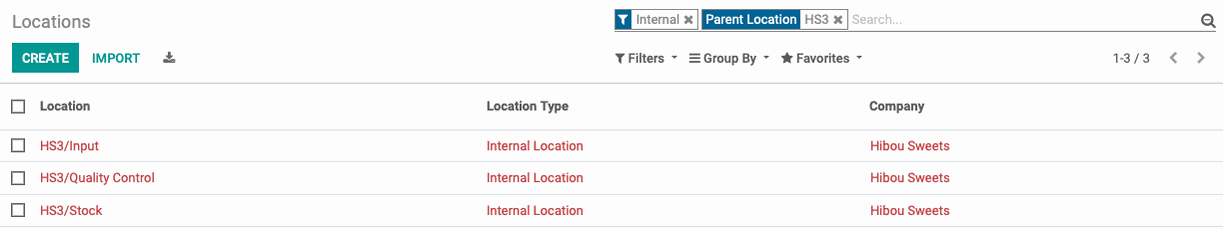

When you're ready, click Save. Selecting the 3-Step option means that Odoo will create an Input location to receive goods and a Quality Control location to perform a quality check.

You can see these new locations by navigating to CONFIGURATION > Locations and searching for your Warehouse.

Good to Know!

Location Names

You can select any location, click Edit, then change its name to one that works best with your company.

Receiving Products

Once you have set up 3-Step Receiving on your Warehouse, you will see its effects on your receipts. To get started, navigate to the Purchase application.

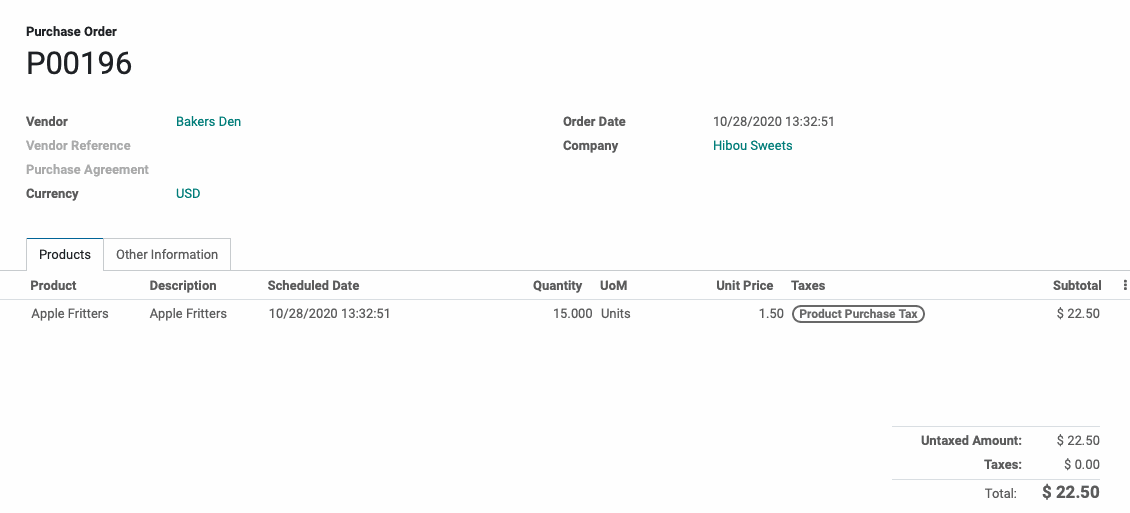

Once there, create a Purchase Order for a storable product. For information on how to create Purchase Orders, please refer to the Purchase Orders documentation.

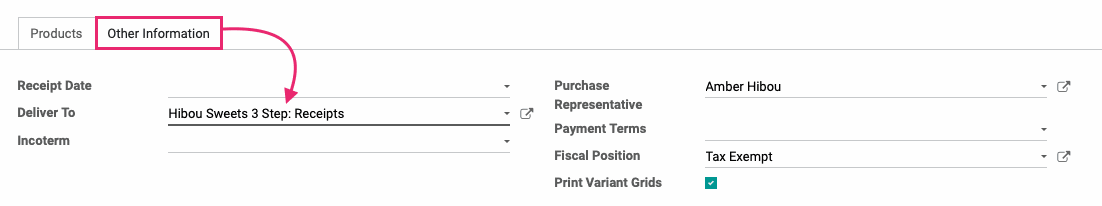

Be sure, on the Other Information tab, that the Deliver To: field is set to use Receipts of the Warehouse you've configured for 3-Step Receiving.

When you're ready, click Save then Confirm before moving to the next step.

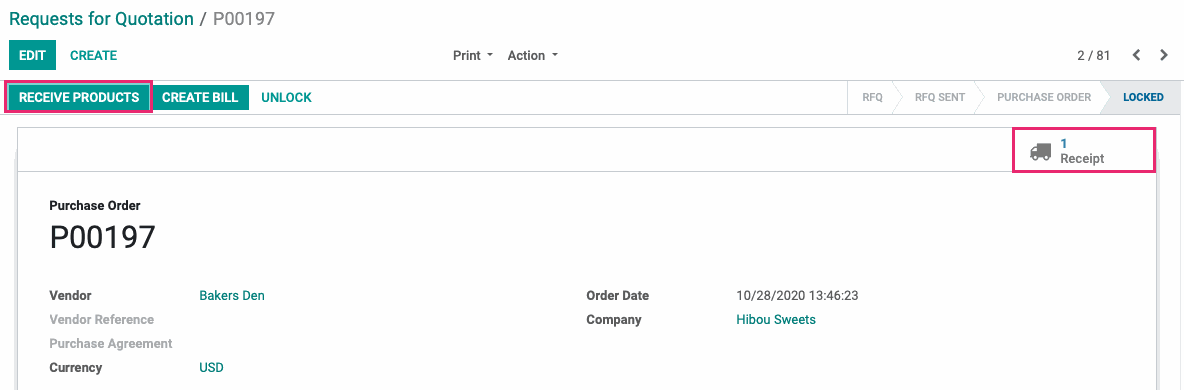

Once you have confirmed the order, click either the Receipt smart button or RECEIVE PRODUCTS.

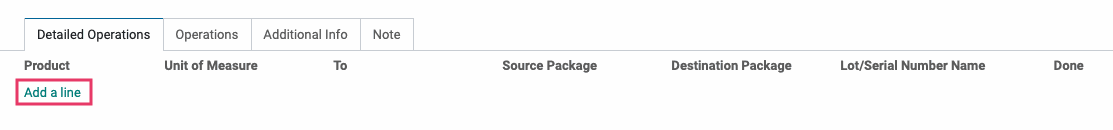

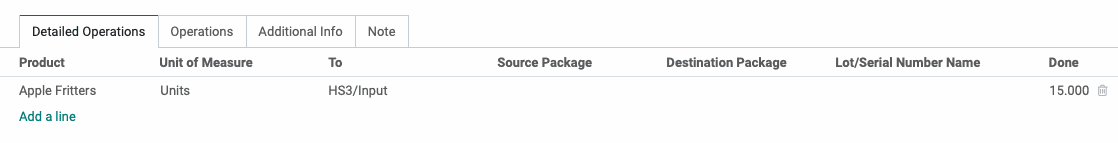

From this receipt, click Edit. Under Detailed Operations, click Add a Line.

This will open a new line, and you'll notice the To: column will be auto-populated with the 2nd step location: Input. On this line, select the product(s) you're recieving as well as the quantity received under the Done column.

When you're done, click Save. Next, complete the receipt by clicking Validate. Now, your goods are in the Input location.

When using 3-step Receiving, Odoo automatically creates a transfer that will move the received product from the Input location to the Quality Control location on your company's receipt Operation Type. Follow the steps below to validate the transfer.

Good to Know!

Note Your PO Number

For ease in moving forward through this document, note your PO number. This will make it easier to locate the records you're looking for in transfers.

Processing the First Transfer

To get started, navigate to the Inventory application.

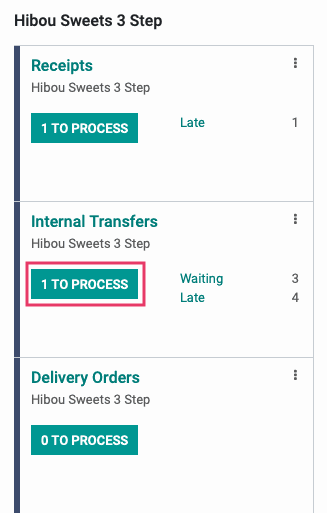

Locate the Internal Transfer card for your Warehouse and click # to process on that card. You can Group By > Warehouse to narrow your search down.

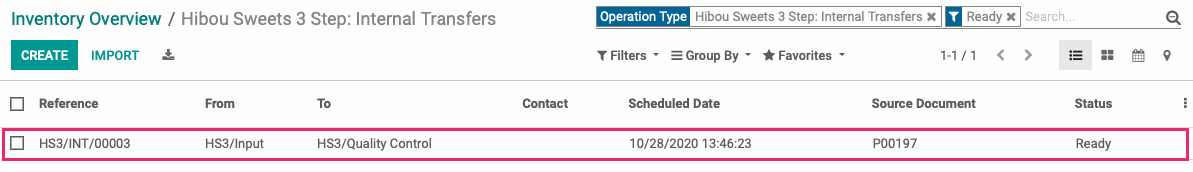

From the list of Internal Transfers, select the transfer corresponding to your Purchase Order. If there are a lot of records, use the PO number you copied to narrow the search.

On the Internal Transfer, you will see that the From and To fields are populated with the WH/Input and WH/Quality Control locations, respectively.

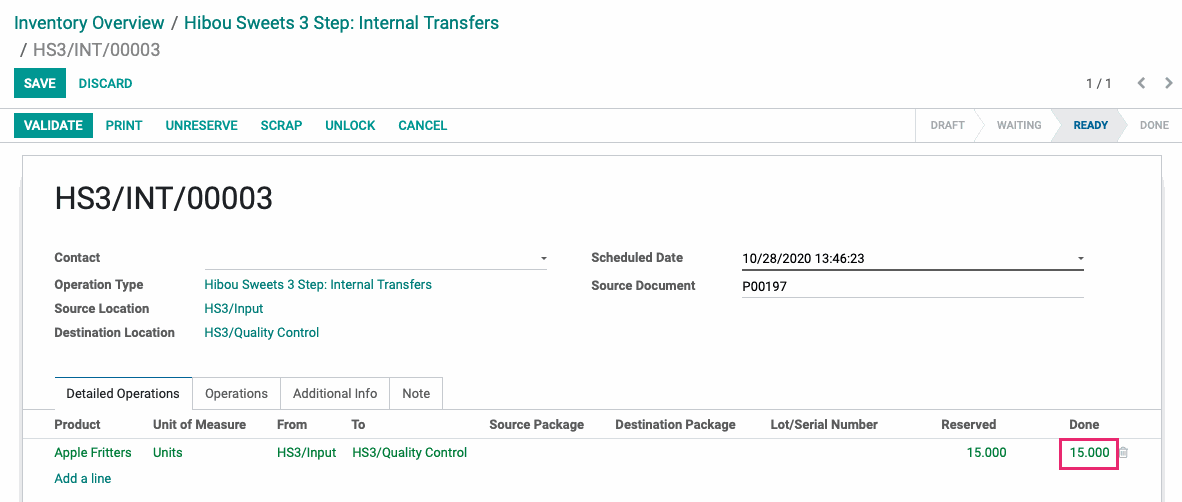

Click Edit, then enter the number of products received in the Done column.

When you're done, click Save then click Validate. At this point, Odoo automatically creates an internal transfer that moves the product from the Quality Control location to the Stock location. Now, you must process this transfer.

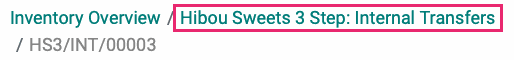

Use the breadcrumbs to navigate back to the list of Internal Transfers for your Warehouse.

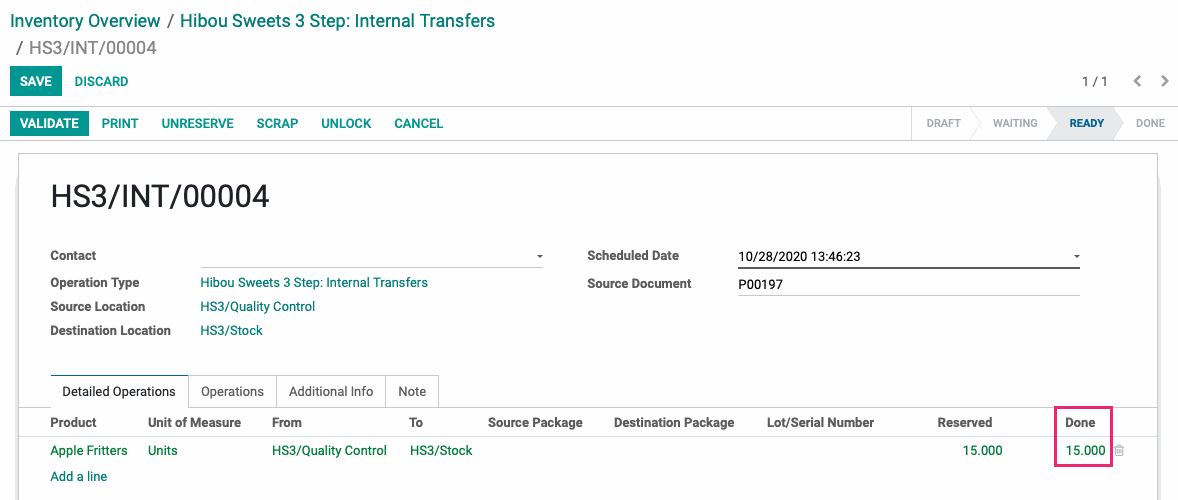

Processing the Second Transfer

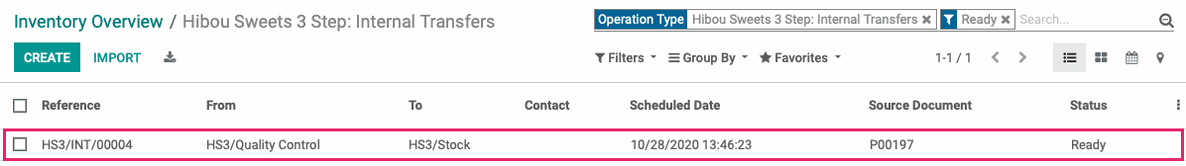

By navigating back, you should see the same list filtered by Warehouse and in Ready status. This is where you'll find the final transfer record from Quality Control to Stock. Click that record.

On this transfer, we will again see that the From location is populated with the WH/Quality Control location and the To location is populated with the WH/Stock location.

Click EDIT, then enter the number of products received in the Done column.

When you're ready click Save. Next, click Validate. Your products are now in Stock, the final step in this receiving process. It's time to review those product moves to verify they are where they should be.

Good to Know!

Putaway Rules

If you have configured a Putaway Strategy on the Product or Product Category of the product being received, they will take effect once you validate the transfer. The destination location on the transfer will still reflect the main Stock location, but once processed, the products will be moved to their more specific stock locations.

For more information on Putaway Rules, please refer to the Putaway Rules documentation.

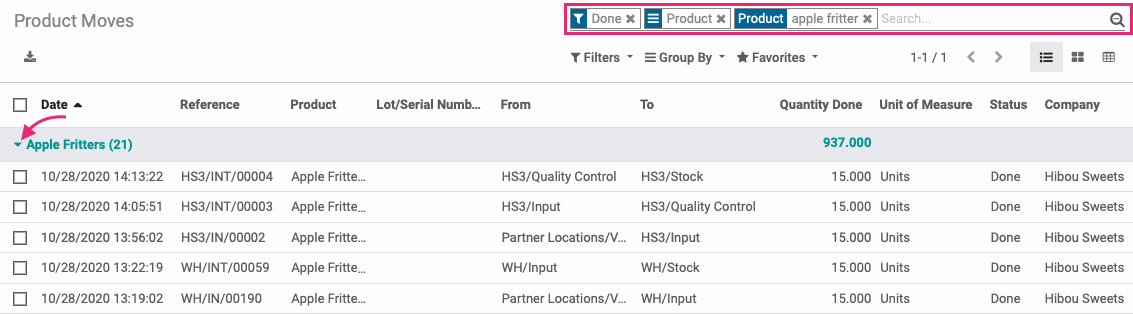

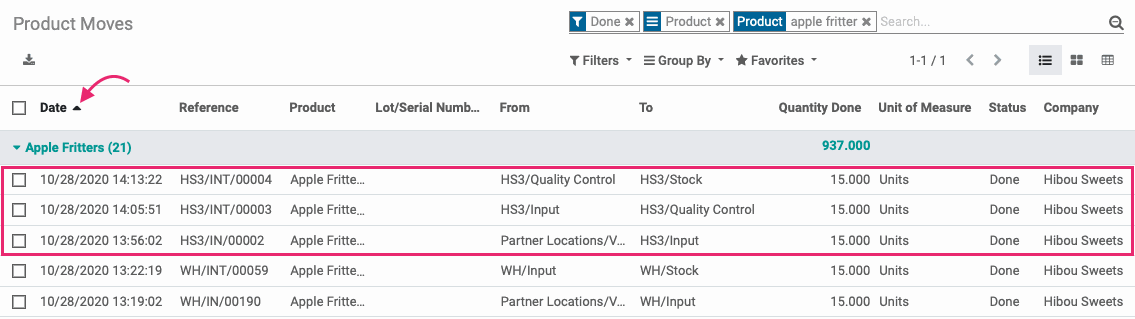

Reviewing Product Moves

Navigate to REPORTING > Product Moves. Use the search bar to locate the product you just received, then expand the group by clicking the down arrow.

If there are a lot of records, you can also click the arrow next to Date to sort by date and find your most recent moves.

From here, we see that our product was received in three moves.

Vendors virtual location to the WH/Input location

WH/Input location to the WH/Quality Control location

WH/Quality Control location to the WH/Stock location