Manufacturing: Operations: Manufacturing Orders

Purpose

This documentation will explain the components of a Manufacturing Order and show you how to create a new order. A Manufacturing Order is a process of creating a deliverable via in-house operations. Odoo Manufacturing makes it possible to manage simple and complex procedures.

Process

To get started, navigate to the Manufacturing app.

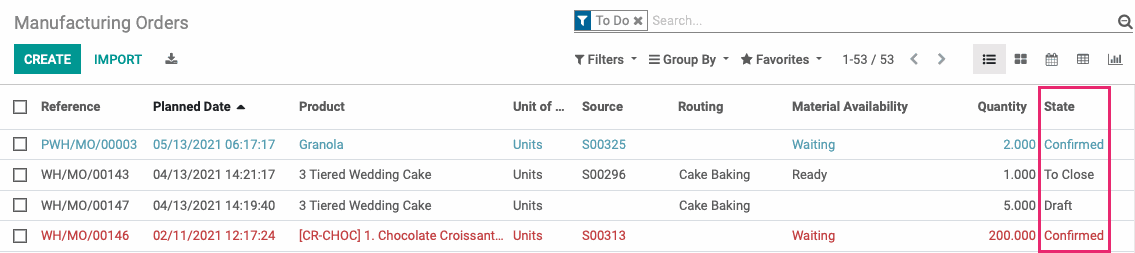

Once there, go to OPERATIONS > MANUFACTURING ORDERS. If you don't have Work Orders enabled, you'll land on this page by default.

This view shows you the dates, products, material availability, and state of each MO at a glance. We've outlined the State column to review the MO states you may encounter.

Draft: The MO has been started and saved as a draft.

Confirmed: The MO has been created and saved.

To Close: The production is complete and you can manually close the MO.

Done: The product is complete and the MO has been closed. You'll need to clear the To Do filter to see Done records.

Items in red are overdue, items in blue are on schedule. Click any record to see further details.

Important!

To create a Manufacturing Order, the product to manufacture must first have a Bill of Materials (BoM). You can find more information in the Master Data > Bills of Materials documentation.

Creating a Manufacturing Order (MO)

Depending on the configuration of your product and system, Odoo may create a MO automatically based on demand. If you need to create a MO manually, click Create from this page.

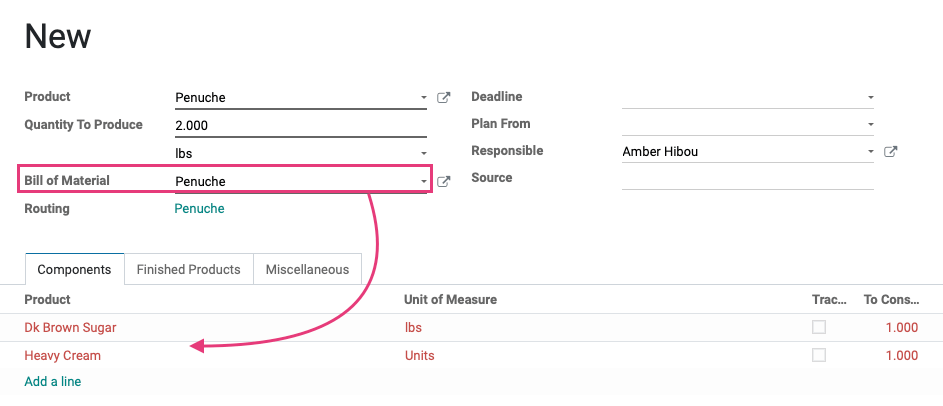

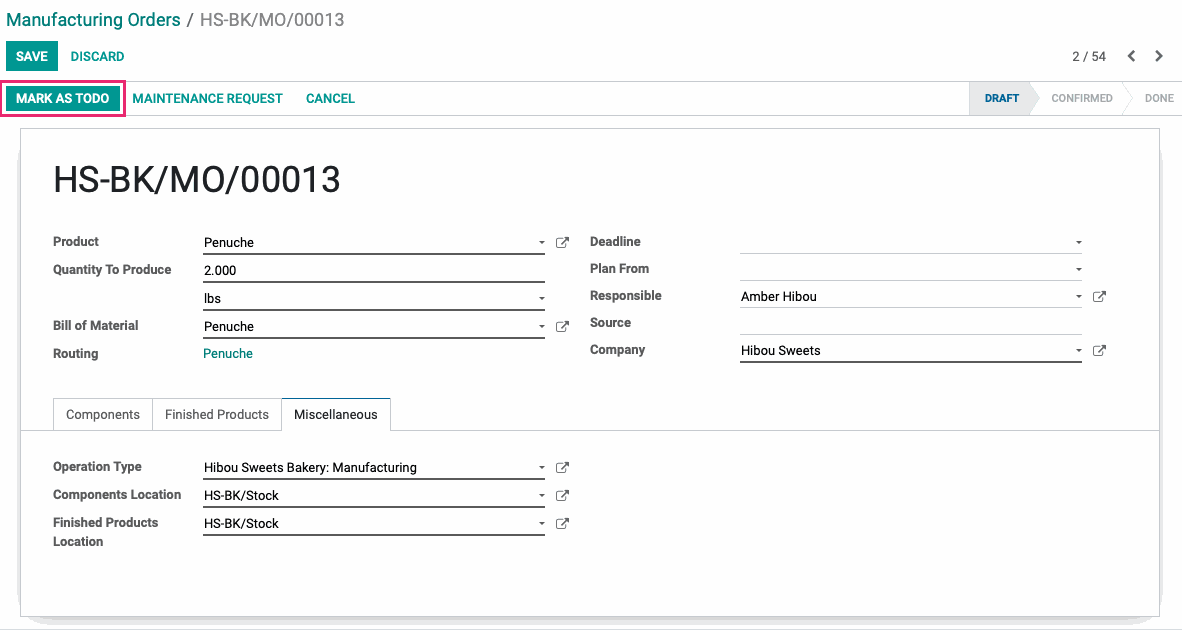

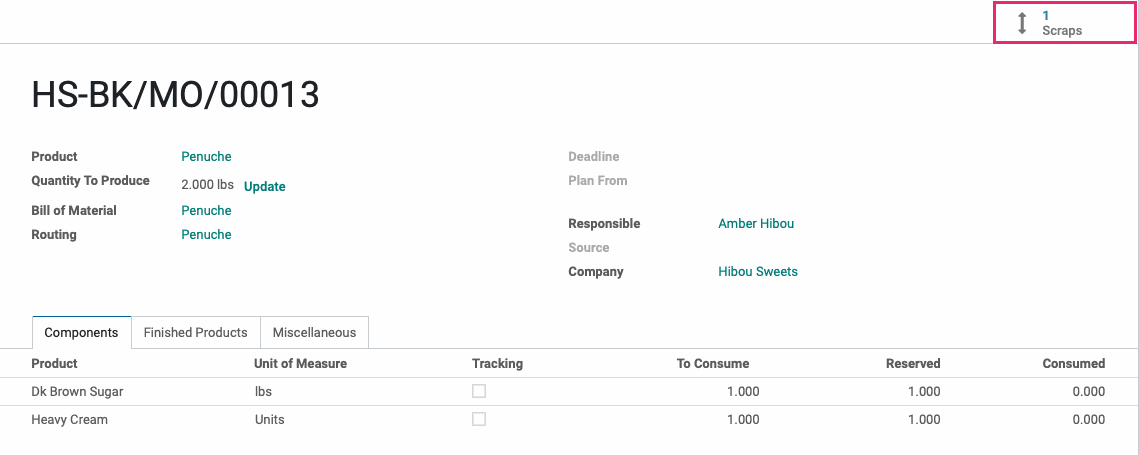

You'll be presented with the following form. We've prepopulated the form with the product "Penuche" to show the process.

Product: This is the item to be produced.

Quantity to Produce: The quantity to be produced based on the Unit of Measure, shown on the next line down.

UoM (label not shown): This field will default to the Unit of Measure the product has been configured with. You may choose to manufacture the product using a different UoM, in the same UoM Category, and Odoo will do the calculations for you.

Bill of Material (BoM): The list of materials needed to manufacture this product. The BoM selected on this line will auto-populate the Product list under the Components tab.

Routing: If defined in the BoM, the Routing will contain the steps needed to manufacture the product.

Deadline: The date the product must be completed.

Plan From: The date you can start the manufacturing process. It will default to the earliest date possible but should be based on the availability of your workcenters, if defined.

Responsible: The name of the contact responsible for the oversight of this MO.

Source: Reference of the document that generated this MO request.

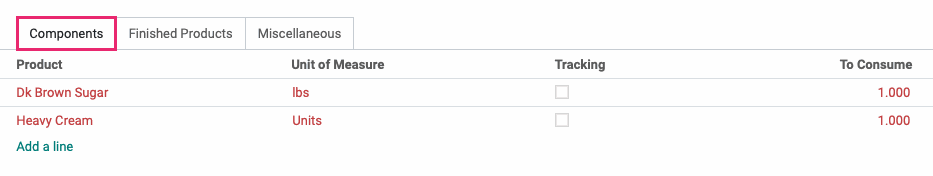

Under the Components tab:

Product: The products are populated based on the BoM selected above. You can click the component to modify the initial demand for this MO.

Unit of Measure: The UoM the product is configured with.

Tracking: This box will be checked if tracking, by lot or serial number, is enabled on your component.

To Consume: The amount of product that will be consumed with this production. This number reflects the UoM specified in the Quantity to Produce at the top of the form.

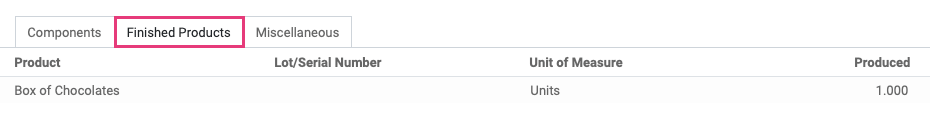

The Finished Products tab will not contain data before the product has been manufactured.

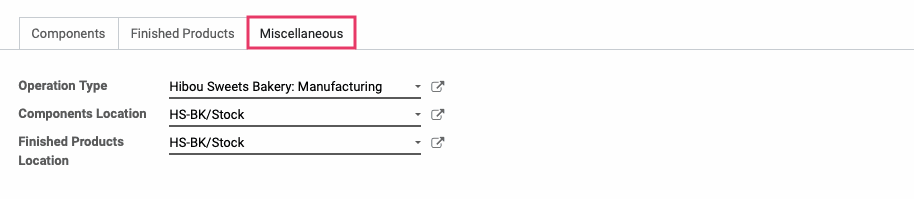

Under the Miscellaneous tab:

Operation Type: The operation entity manufacturing this product.

Components Location: The location where the components are stored pre-production.

Finished ProductsLocation: The location where the finished product will be stored post-production.

Once you've entered all information, click Save to put it in Draft status. To confirm the manufacturing order, click Mark as Todo.

Good to Know!

There are three types of Manufacturing methods: 1-step, 2-step, and 3-step, which are configured on individual warehouses in the Inventory app, then go to Configuration > Warehouses.

These methods incorporate picking and transferring. Because they can range from simple to intricate, we've created separate documentation to outline the full workflow of each. For those details, please refer to Manufacturing Workflow documentation.

Options on a Confirmed Manufacturing Order

Since the full workflow will be explained in the Manufacturing Workflow documentation, we'll briefly go over what the options are on a Confirmed Manufacturing Order here.

Check Availability

The Check Availability step is required before you start the process of manufacturing. This step checks Odoo stock for all necessary components and reserves them for your order if they're available. When clicked, components that can be reserved will display in black. All others will display in red, and you'll need to ensure they're in stock before continuing.

Once reserved, you'll have the option to Unreserve to release the components and set them as available.

Plan

This button will only display if there is a routing set on the Bill of Materials. The Plan button will add your job to the work center's schedule, regardless of component availability. Once planned, you'll also have the option to Unplan and remove the job from the schedule.

Scrap

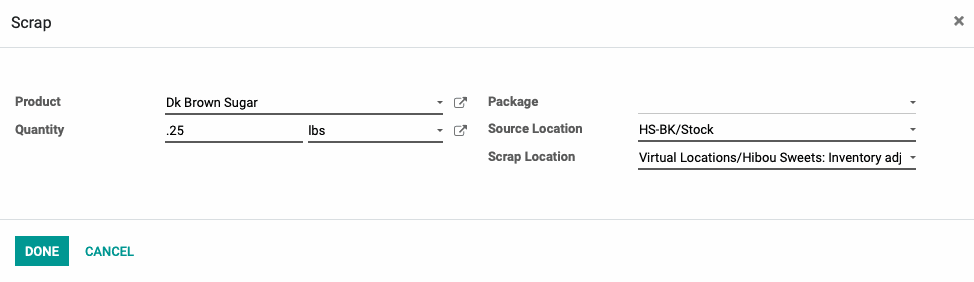

The Scrap button will allow you to mark some or all components as damaged or unusable (e.g. expired). In this example, we're showing that .25 lbs of brown sugar will be scrapped.

You can Scrap a component before or after checking availability.

Now that this amount is scrapped, you'll see a Scraps smart button on the manufacturing order.

Unlock

Use Unlock to modify a confirmed manufacturing order. Once clicked, you can do the following:

Adjust the quantity to produce

Add products to the components tab not included in the BoM

Increase the quantity for existing components by clicking the individual line items

Adjust the deadline date

Adjust the Plan From date

Change the responsible contact

Modify the Source field

When you're done modifying, click Lock to save your changes. Note that, depending on your database configuration, regular users may not have this option.

Produce

This button will only display if there is no routing on the Bill of Materials.

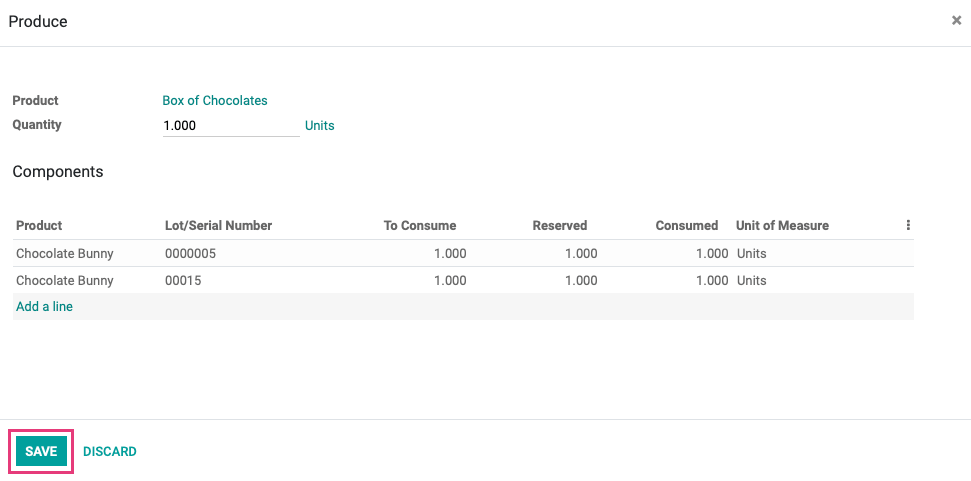

Outside of component availability, if your manufacturing order isn't waiting on any other production or operation, you'll see the Produce button. This will trigger the manufacturing process of your product.

Once clicked you'll see a confirmation window to validate your order. On this modal window, you can adjust the quantity to produce and add lines to the component products.

Once you've verified the order, click Save to start production.

After production, the Finished Products tab will display the product and quantity produced.

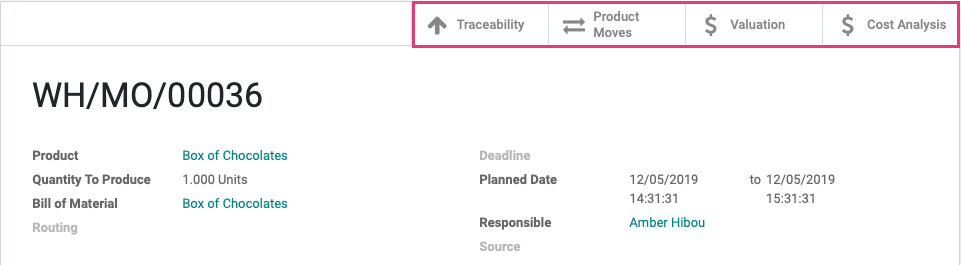

Once the order is complete, click Mark as Done. Your MO will now show you four new smart buttons for your reference.