Manufacturing: Manufacturing Planning : Master Production Schedule

Purpose

The Master Production Schedule, in the Odoo 14 Manufacturing application, both plans and triggers the manufacturing of specific products based on an official forecast, seasonal trends, or foreseeable demand. This document covers what each field means.

Process

To get started, navigate to the Manufacturing app.

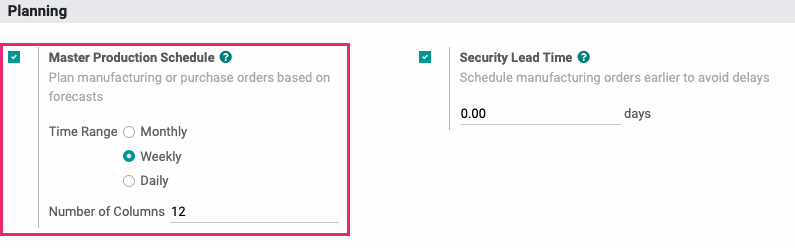

First, let's enable the functionality by going to Configuration > Settings. Under the Planning section, enable Master Production Schedule.

Leave the default settings and click Save.

Next, go to the newly added menu: PLANNING > MPS > MASTER PRODUCTION SCHEDULE.

Adding a Product to the Schedule

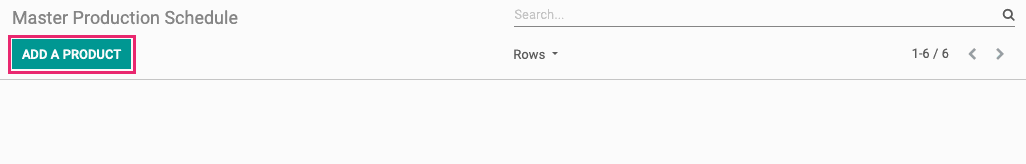

If you've added no products to the schedule, your initial view will be empty, with only the option to add a product. Click ADD A PRODUCT to get started.

This opens the Add a Product modal window with the following fields:

Product: Select the product to add to the schedule.

Production Warehouse: Select the location where this product is manufactured.

Safety Stock Target: Enter the number of units you'd like to always have on hand.

Minimum to Replenish: Enter the minimum number of units to manufacture at one time.

Maximum to Replenish: Enter the maximum number of units to manufacture at one time.

When all information is entered, click SAVE.

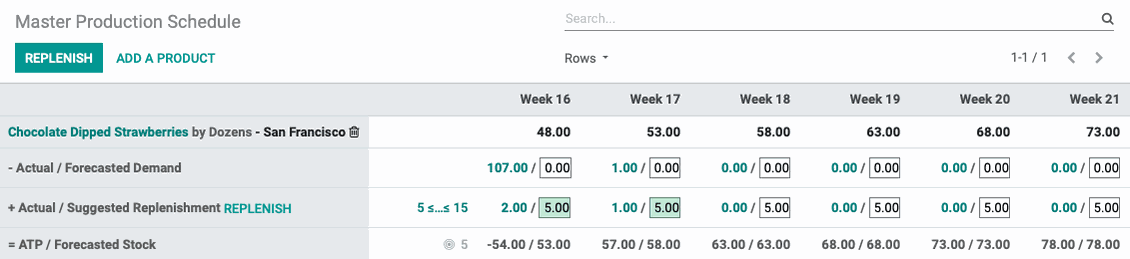

After your product is added, you'll see several lines of data relating to this product. This screen will have a horizontal scroll bar to see data to the far right. Some fields are adjustable, and some are not. We'll discuss each of these below.

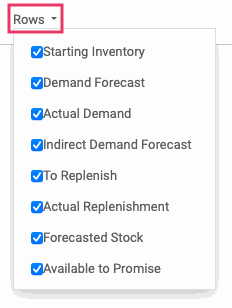

You'll also have the option to add more rows of data by enabling them in the Rows drop-down menu. The additional rows can only be viewed and not adjusted in this view. For our example, we'll select all options.

How it Works

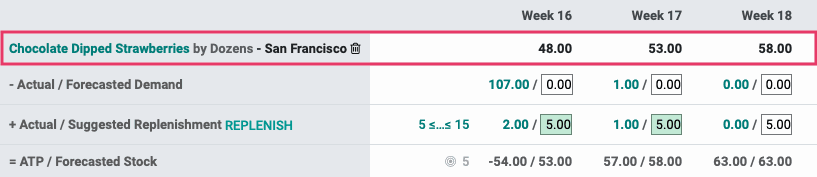

Let's look at our weekly Chocolate Dipped Strawberries situation with the following example.

Starting Inventory

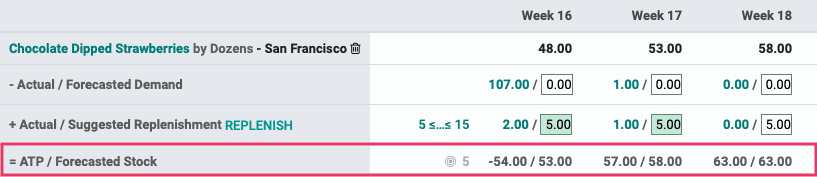

Example: Our Starting Inventory for Week 16 is 48.00 units. Because our Suggested Replenishment is 1, the Starting Inventory increases by one each week.

This number is your available product in stock. Odoo populates this data for you based on actual Inventory.

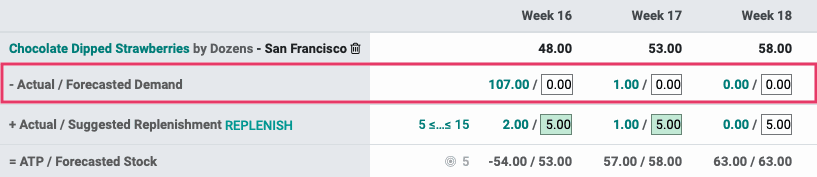

Actual / Forecasted Demand

Example: Our Forecasted Demand for Week 16 is 0.00 and the Actual Demand is 107.00.

The Actual Demand figure, shown to the left of the Forecasted Demand, reflects the actual number of this product scheduled for delivery. This number is a helpful guide when entering a forecasted figure.

Forecasted Demand is adjustable based on your estimations, and it can be positive or negative, depending on your expectations. For example, if you're expecting a return of several items, this would record as a negative demand because it would be adding to your stock on hand.

Actual / Suggested Replenishment

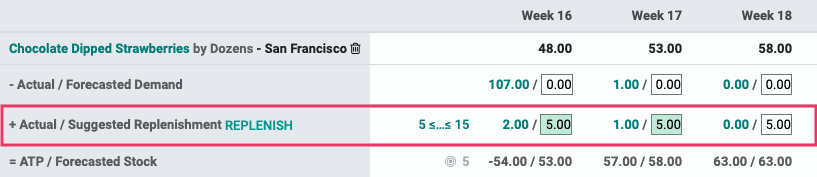

Example: Our Actual Replenishment is 2. Our Suggested Replenishment was automatically set to 5 because that is the Safety Stock quantity we wanted to keep on hand.

Actual Replenishment represents the total quantity of this product in active RFQs, Receipts, and Manufacturing Orders.

Suggested Replenishmnent will range between the Minimum to Replenish and Maximum to Replenish figures you entered when you created the product entry on the schedule. This number is calculated as follows: (Starting Inventory - Demand Forecast), but you can override it by entering a different number in that field.

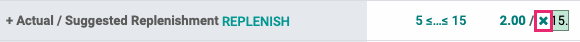

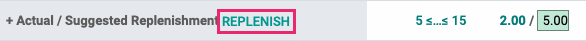

You'll know if the number entered is an override because you'll see the icon next to it. Click the icon to clear the number and, once again, allow Odoo to calculate it for you.

You can modify your Minimum to Replenish and Maximum to Replenish quantities from this page directly by clicking the figure on the To Replenish line.

You can also start the process to replenish your stock for this month by clicking REPLENISH. This will immediately create a Manufacturing Order.

Available to Promise / Forecasted Stock

Example: Our Available to Promise (ATP) for Week 16 is -54, and our Forecasted Stock is 53.

Stock that is Available to Promise (AVP) represents inventory that is not reserved in other operations. Forecasted Stock represents the approximate stock that should be available for this period if no other operations are created to reserve it.