Manufacturing: Manufacturing Planning : Master Production Schedule

Purpose

The Master Production Schedule both plans and triggers the manufacturing of specific products based on an official forecast, seasonal trends, or foreseeable demand.

The purpose of this document is to teach you the basics of the Master Production Schedule page found in the Odoo 13 Manufacturing application under the Planning menu.

If you don't see the Planning menu, be sure that the Master Production Schedule is enabled on the Manufacturing app in CONFIGURATION > SETTINGS.

Process

To get started, navigate to the Manufacturing app.

Once there, click PLANNING > MASTER PRODUCTION SCHEDULE.

Adding a Product to the Schedule

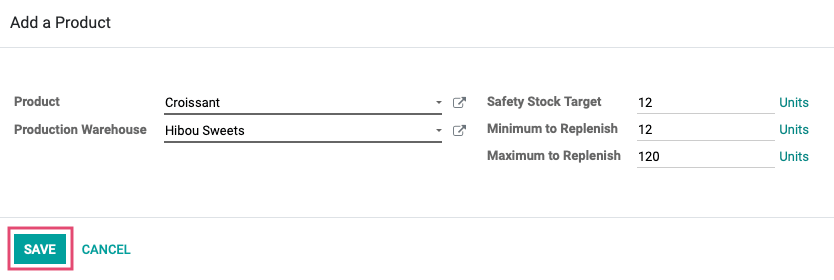

If you've added no products to the schedule, your initial view will be empty, with only the option to add a product. Click ADD A PRODUCT to get started. You'll see the following form fields:

Product: Select the product to add to the schedule.

Production Warehouse: Select the location where this product is manufactured.

Safety Stock Target: Enter the number of units you'd like to always have on hand.

Minimum to Replenish: Enter the minimum number of units to manufacture at one time.

Maximum to Replenish: Enter the maximum number of units to manufacture at one time.

When all information is entered, click SAVE.

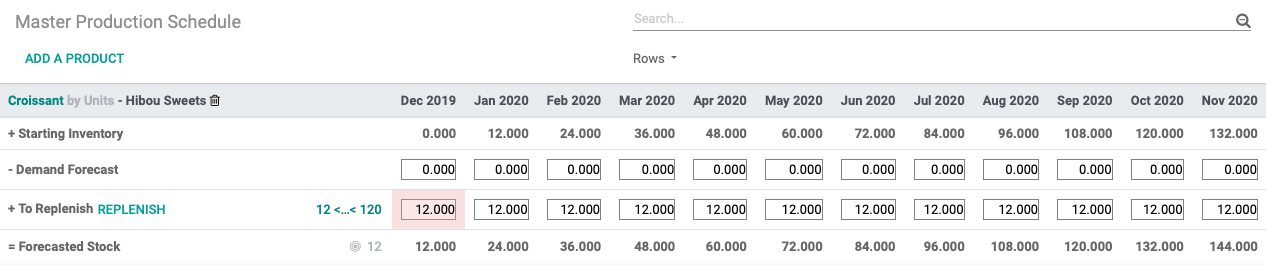

After your product is added, you should see multiple fields where you can adjust the numbers you entered above, individually.

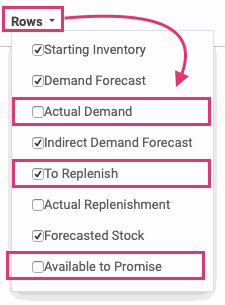

You'll have the option to add more rows of data by enabling them in the Rows drop-down menu. The additional rows can only be viewed and not adjusted in this view. For our example, we'll leave the menu at the default settings.

How it Works

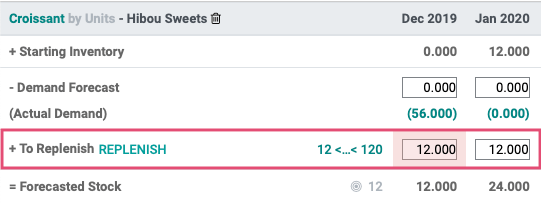

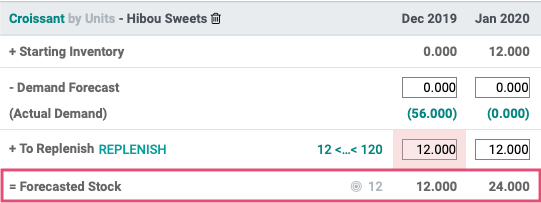

Let's look at our December/January croissant situation with the following example.

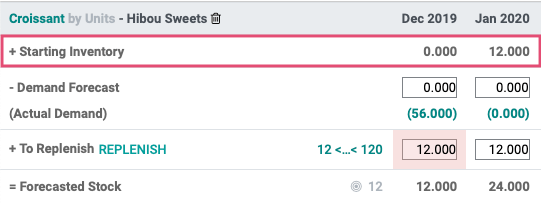

Starting Inventory

Example: Our Starting Inventory for December is 0.00 units because we have no croissants in stock.

This number is your available product in stock. Odoo populates this data for you, based on actual Inventory.

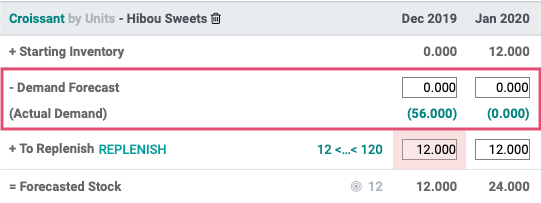

Demand Forecast

Example: Our Demand Forecast for croissants is set to 0.00 and the Actual Demand for this month was 56.00.

Demand Forecast is adjustable based on your estimations. The Actual Demand figure, shown on the next line, reflects the actual number of products with Manufacturing Orders for this month. This number is a helpful guide when entering a forecasted figure.

Demand Forecast can be positive or negative, depending on your expectations. For example, if you're expecting a return of several items, this would record as a negative demand because it would be adding to your stock on hand.

To Replenish

Example: Our To Replenish was automatically set to 12 because that is the Safety Stock quantity we wanted to keep on hand.

This number will range between the Minimum to Replenish and Maximum to Replenish figures you entered when you created the product entry on the schedule. This number is calculated as follows: (Starting Inventory - Demand Forecast), but you can override it by entering a different number in that field.

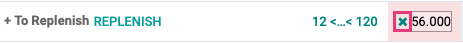

You'll know if the number entered is an override because you'll see the icon next to it. Click the icon to clear the number and, once again, allow Odoo to calculate it for you.

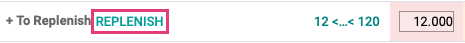

You can modify your Minimum to Replenish and Maximum to Replenish quantities from this page directly by clicking the figure on the To Replenish line.

You can also start the process to replenish your stock for this month by clicking REPLENISH. This will immediately create a Manufacturing Order.

Forecasted Stock

Example: Our Forecasted Stock was automatically calculated as 12.00, which matches our Target number.

As you can see from our example, the Forecasted Stock for December becomes our Starting Inventory for January. The hard coded numbers will adjust based on real-time information from your database.